Brewing companies face an ongoing challenge to reduce the amount of water consumed in their processes and must constantly seek new ways of achieving, and surpassing, their environmental impact targets.

The AESSEAL Academy is a resource to find out some of the basics (and more complex concepts) of the fluid & gas sealing industry. Experts offer their best advice on industry best practice and tips & tricks to improve efficiency and reliability.

Does your factory or plant experience a lot of downtime? Do you keep seeing repeated bearing costs appearing in your invoices? If it’s happening regularly, it can get expensive, trigger unplanned downtime and result in lost production, increased maintenance costs and additional spare part inventory.

What can you do to help save vast amounts of water? Take a look at the mechanical seals and gland packing on the rotating equipment in your factories and plants.

In the long term lip seals are more expensive than bearing protectors. Ok, so maybe the initial outlay of a bearing protector is more than a lip seal, but payback is so quick you’ll be wondering why it’s taken you so long to change over.

Improving energy efficiency is becoming increasingly important to today’s industrial companies. The benefits are reduced operational costs (leading to increased profitability) and reduced impact on the environment.

The article looks at how it’s possible to reduce energy usage by up to 96% through selecting more energy efficient mechanical seal flush plans.

A question that comes up often is, “why should I use mechanical seals instead of packing when packing is cheaper?”.

It has long been recognized that as many as 91% of all the rolling element bearings installed in the world’s machinery fall short of reaching the manufacturer’s calculated L-10 life.

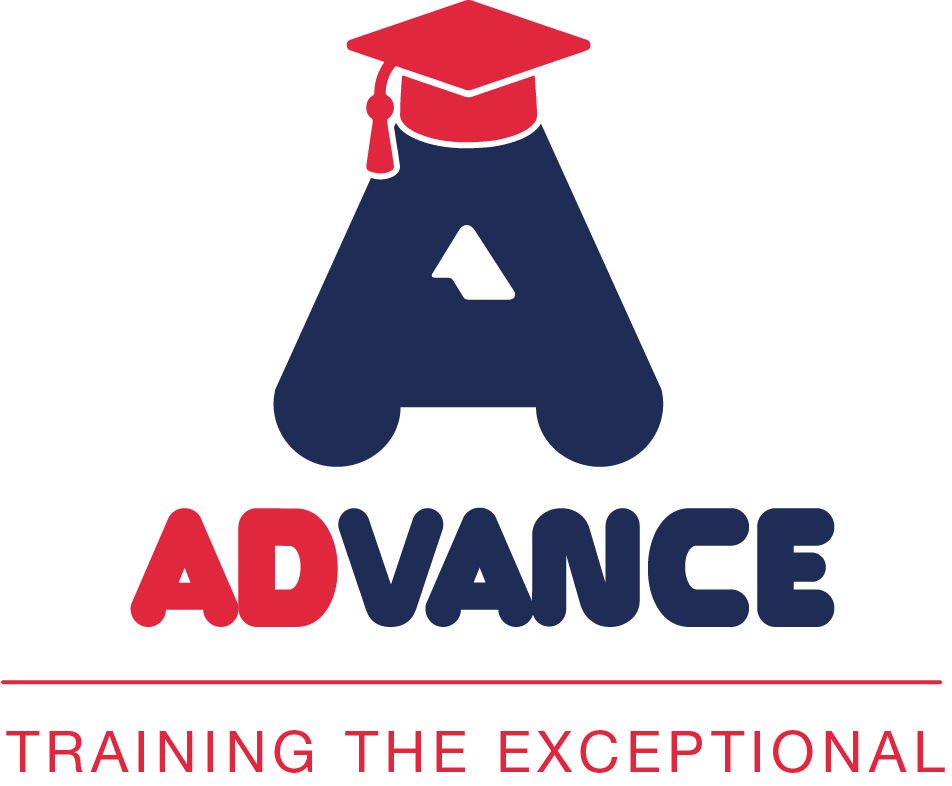

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.