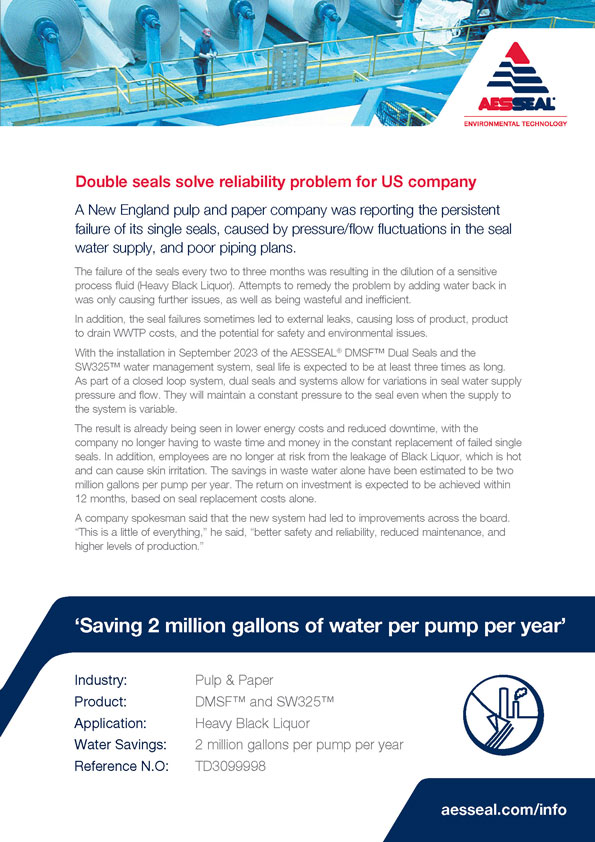

AESSEAL® have been helping the pulp and paper industry improve reliability, reduce water and energy consumption for many years.

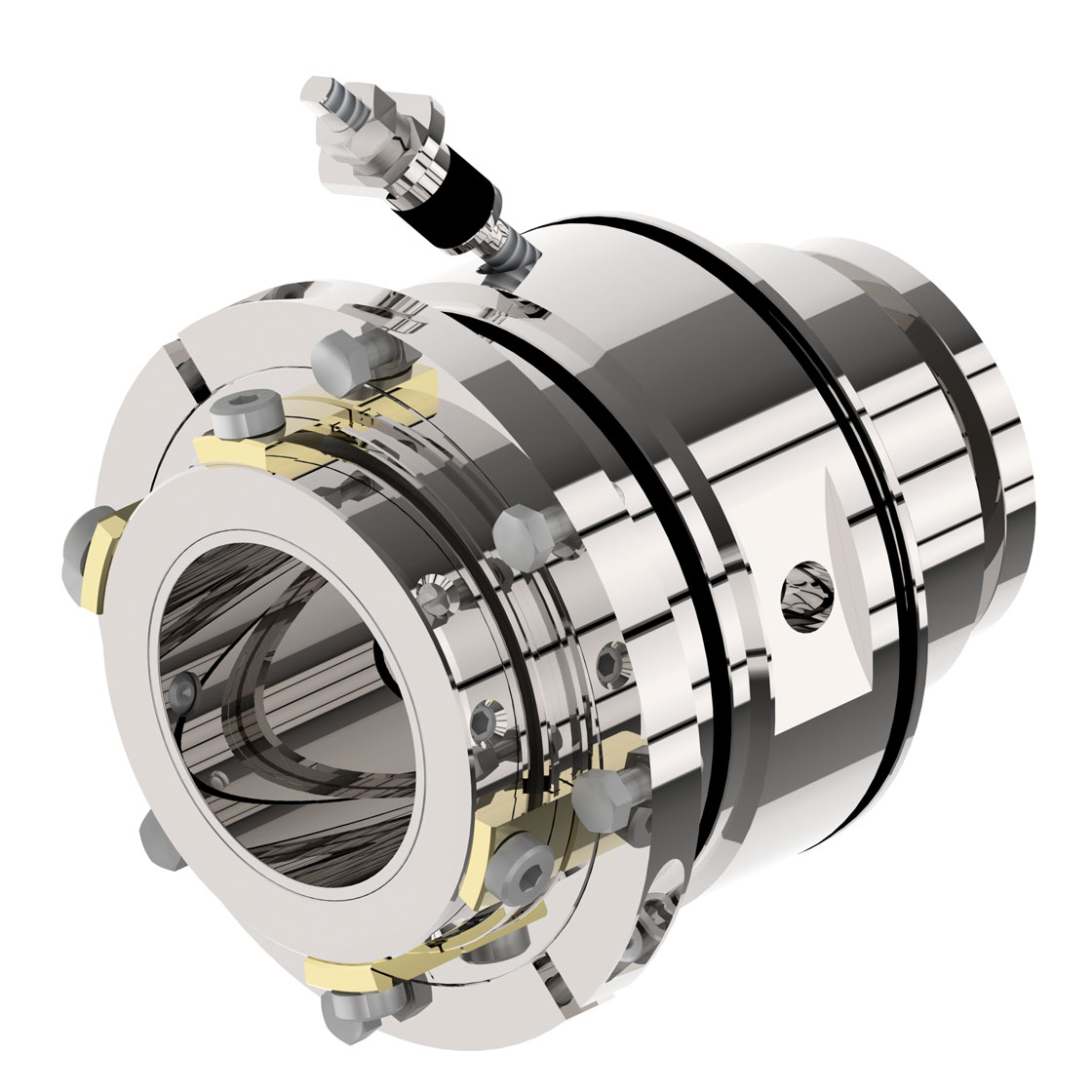

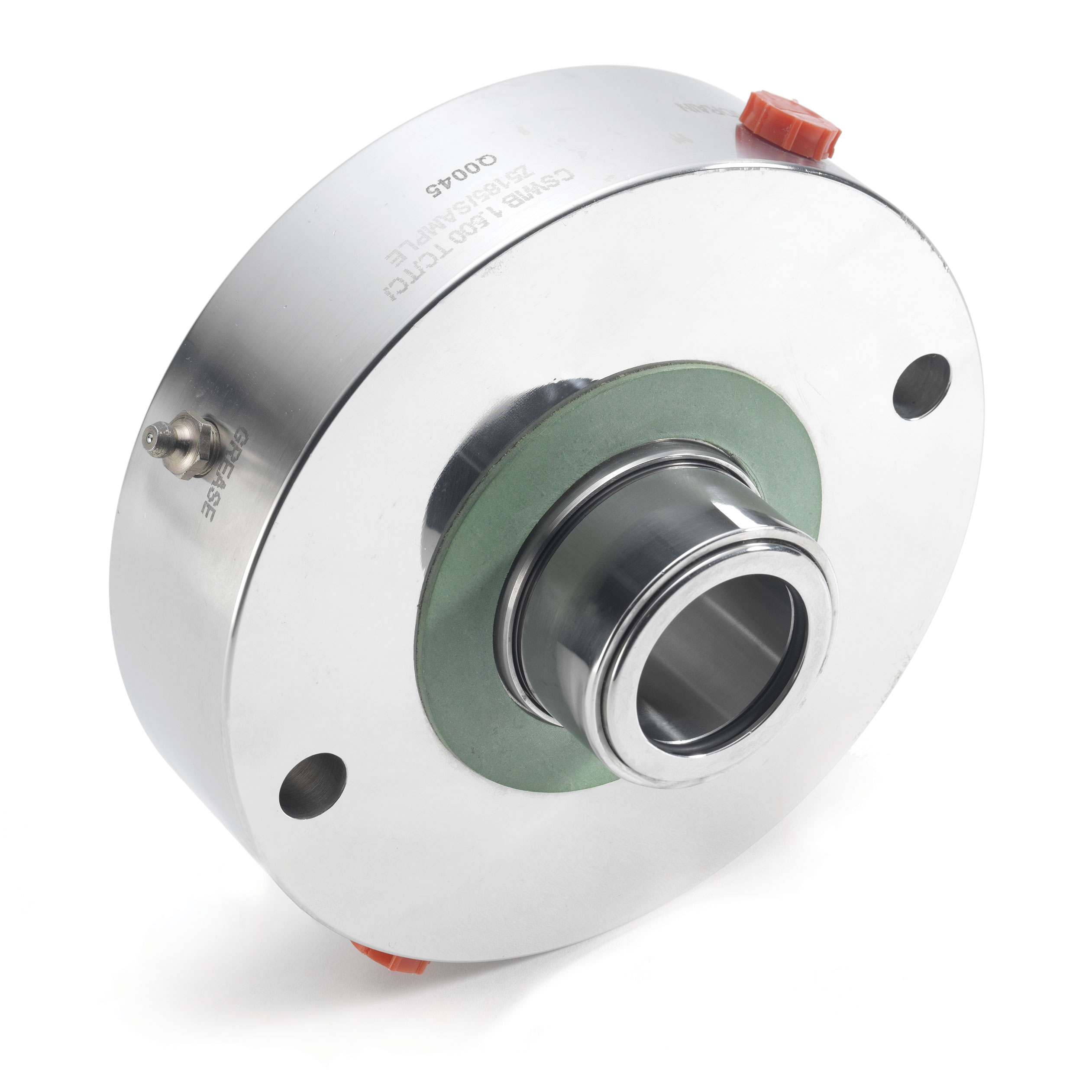

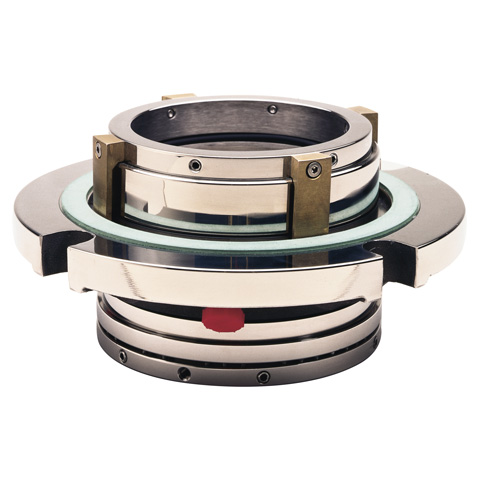

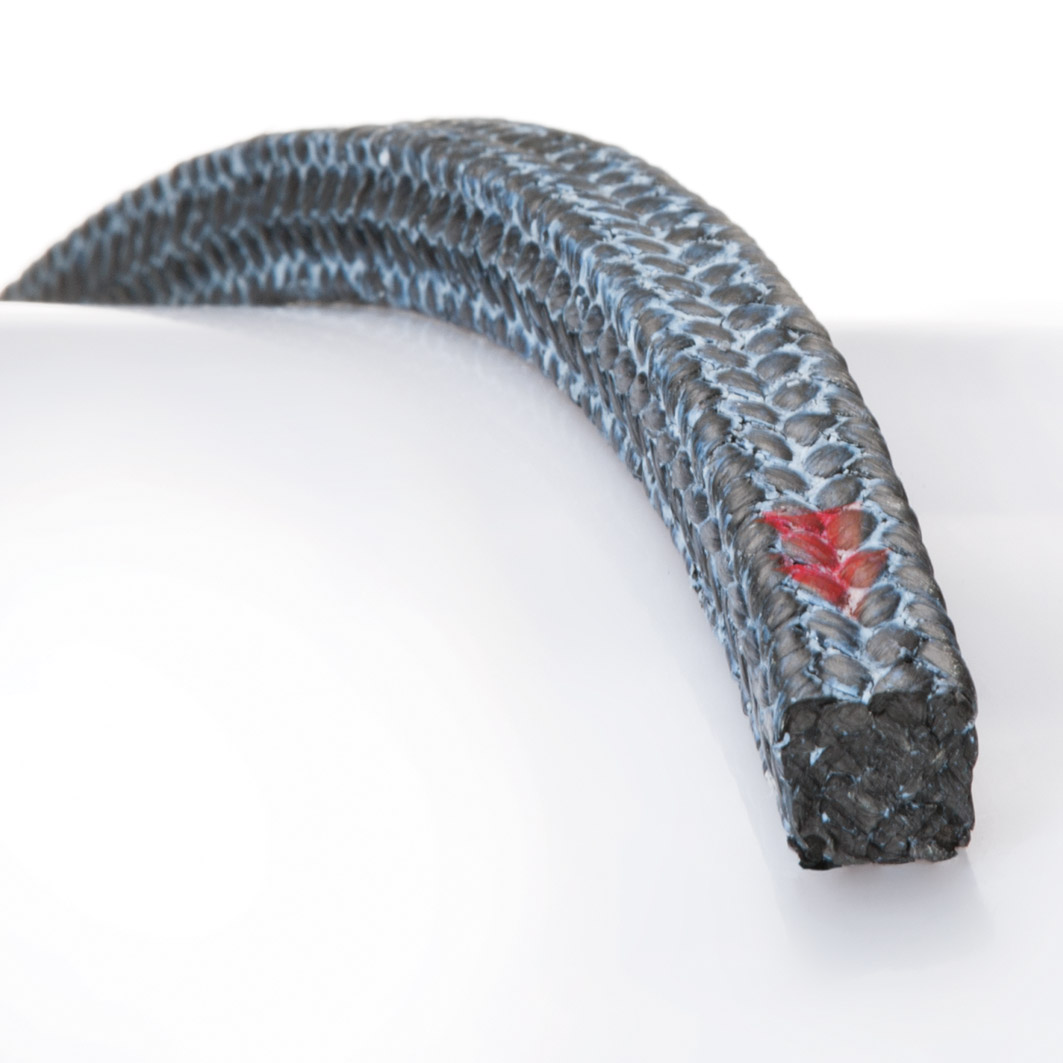

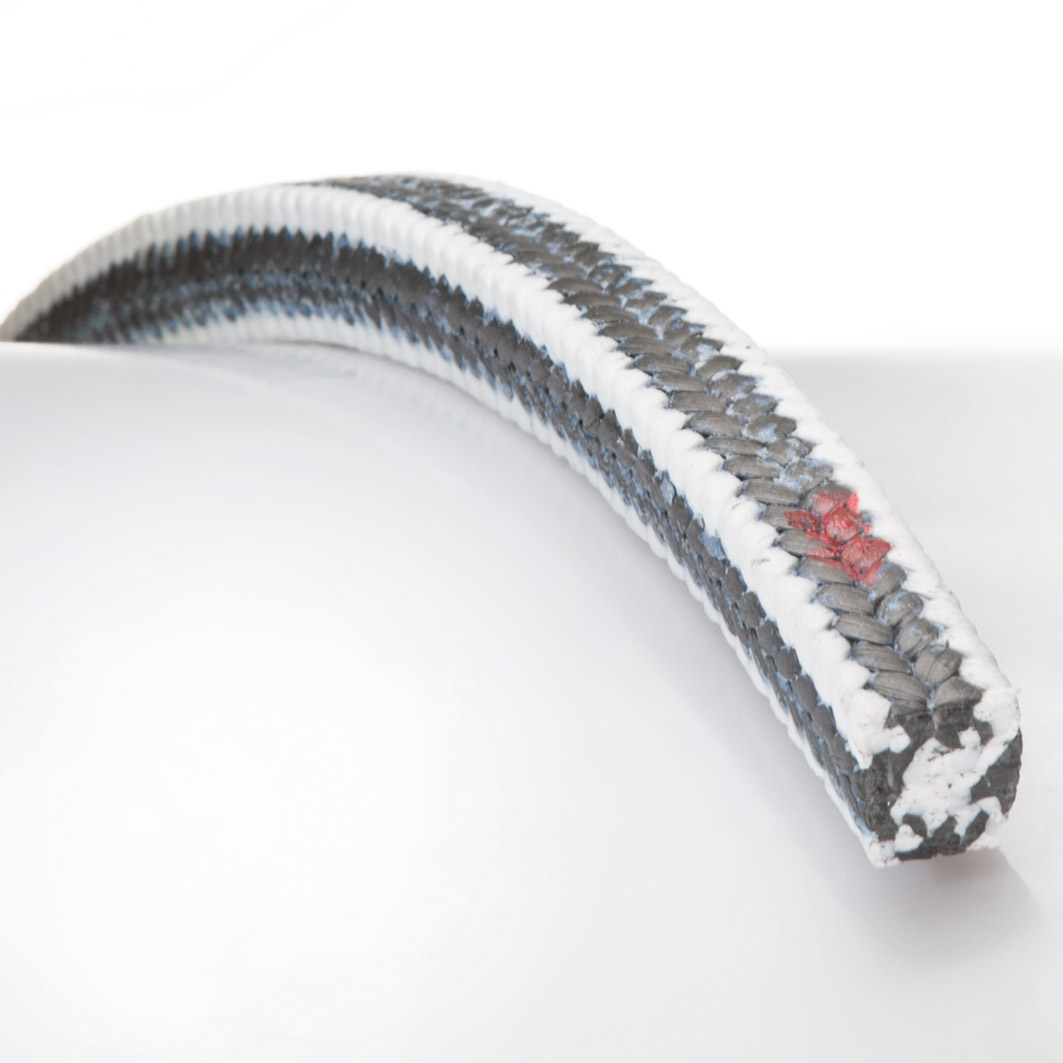

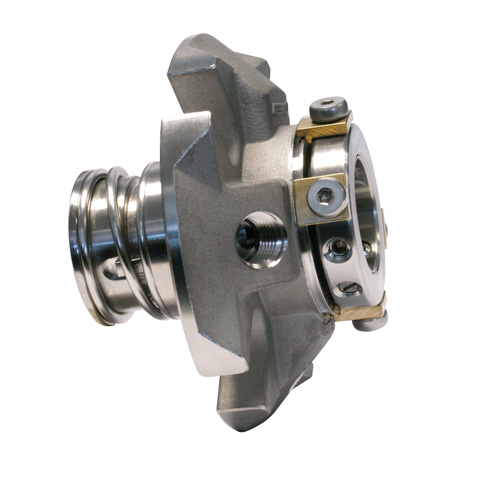

With sealing solutions for the whole process from wood pulp, to the coatings kitchen. AESSEAL® work with customers to ensure that the best most efficient sealing solution is provided.

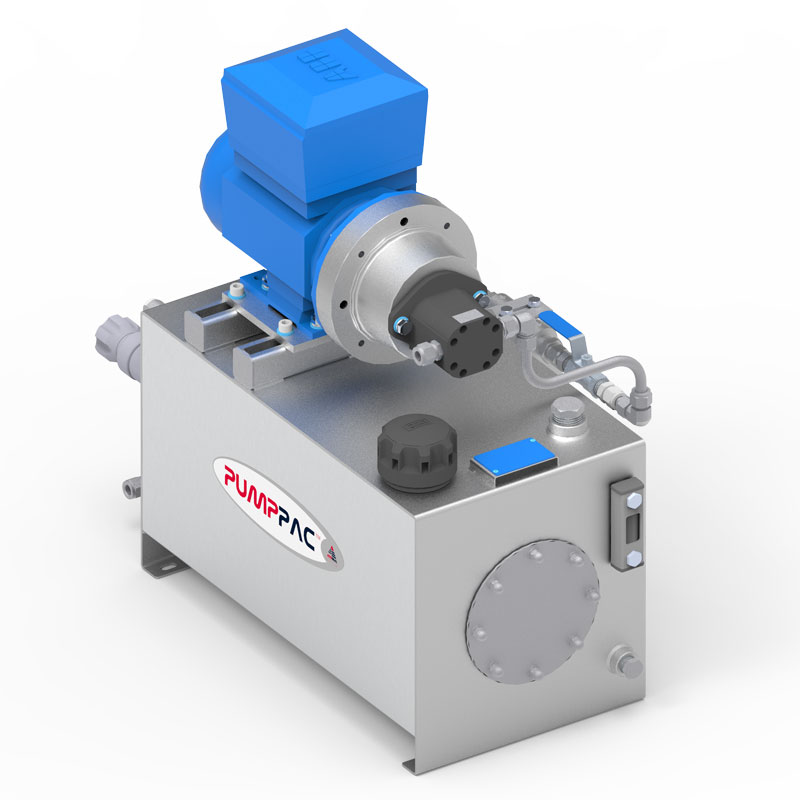

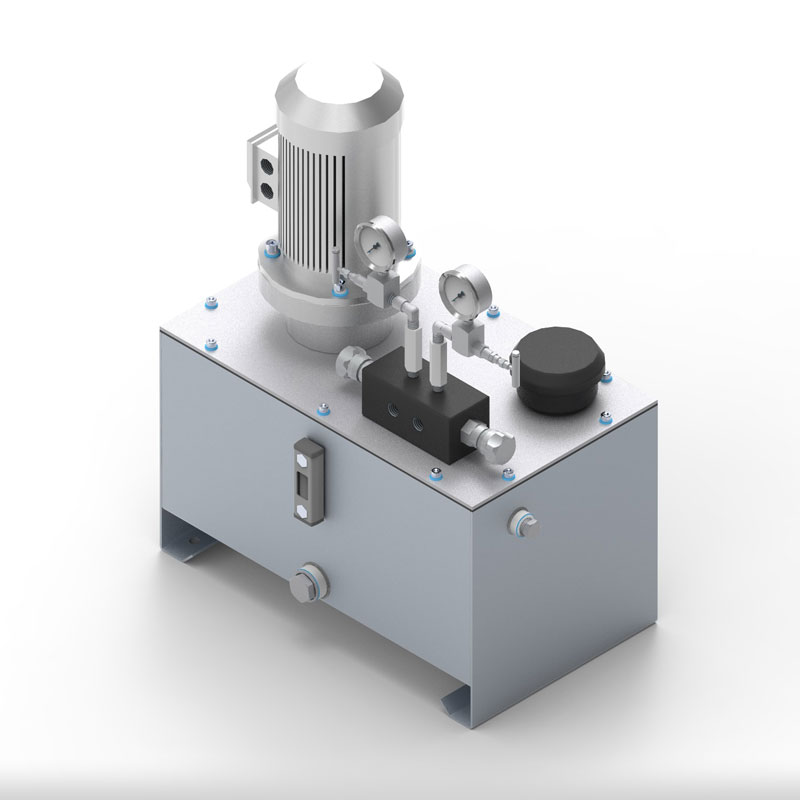

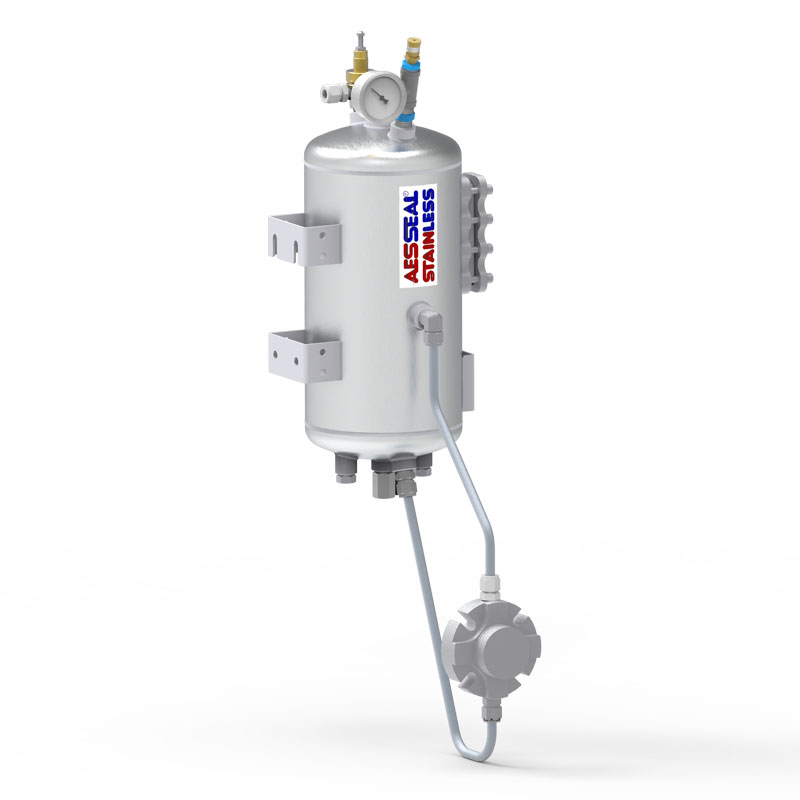

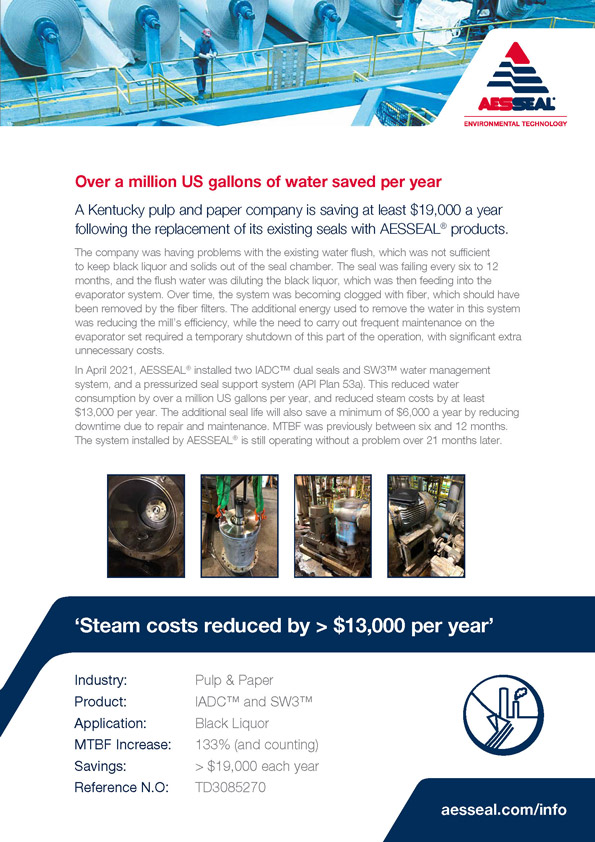

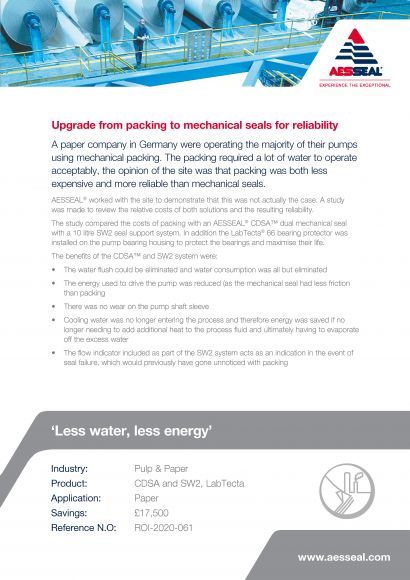

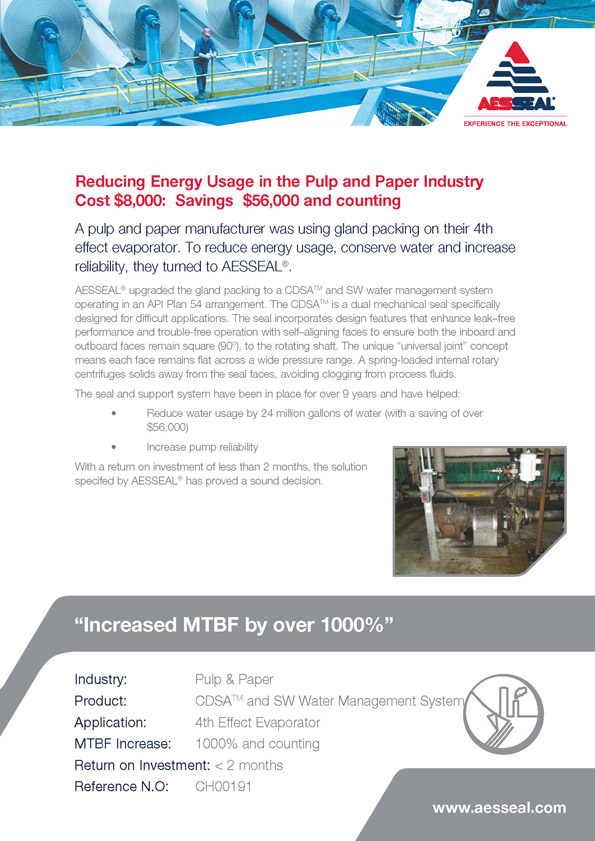

AESSEAL® water management systems in conjunction with dual seals have saved customers millions of gallons of water by recycling water rather than letting it enter the process or the effluent handling system. By preventing the injection of cold water into the process, energy consumption has also been significantly reduced saving customers hundreds of thousands of dollars. As an additional benefit the application of these systems has improved reliability by ensuring the seal operates in a controlled environment.

A unique opportunity for the Pulp and Paper industry

You could reduce energy usage by 50,000 mmBTU on your multiple-effect evaporators.

Watch the full video

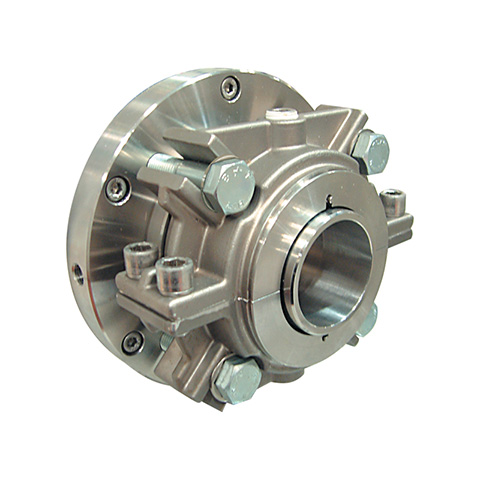

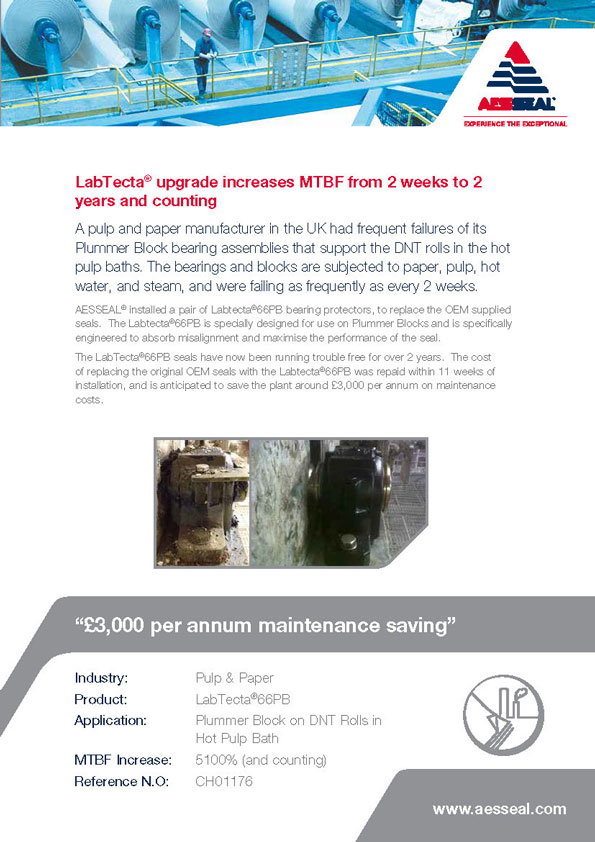

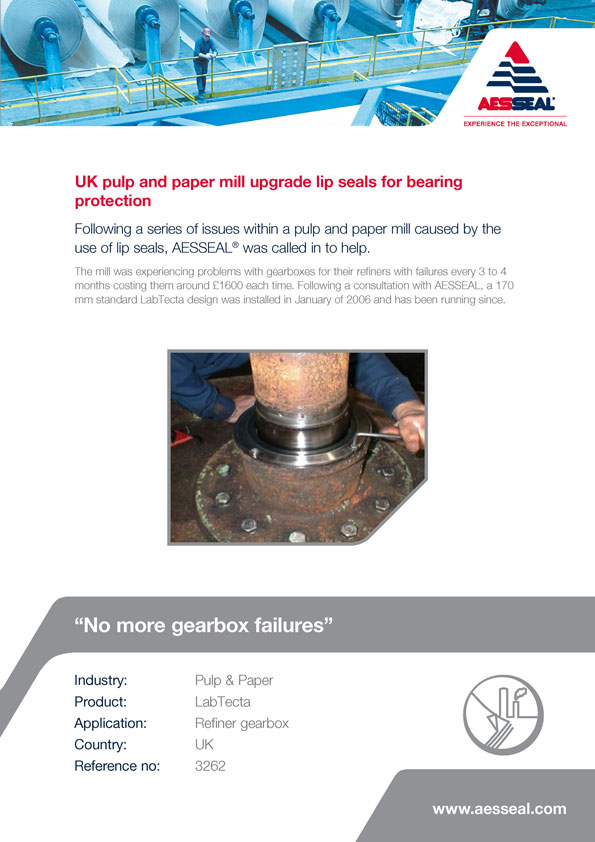

Upgrading lip seals to AESSEAL® bearing protectors has driven significant reliability improvements in the pulp and paper industry. Bearing protection products are available for pumps, motors and pillow/plummer blocks. For more information about how you could improve reliability see case histories.